Designing a warehouse ergonomics that goes beyond workstations isn’t really about complexity—it’s about honesty. There’s a moment in every busy warehouse when you realize the workstation checklists and neatly laminated posters aren’t cutting it anymore. People aren’t static, tasks aren’t isolated, and the real world has no patience for warehouse ergonomics programs that pretend everything happens inside a tidy rectangle of floor tape. The work follows people everywhere, and the ergonomic risks follow right behind. That’s where a broader, more fluid approach starts to matter.

A Fluid Approach to Warehouse Ergonomics

The Work Doesn’t Stay in One Place

Even the best-designed packing bench can’t protect someone hauling pallets across uneven concrete or twisting around a crowded aisle to grab a tote that should’ve been closer. So the thinking has to shift from “fix the station” to “follow the workflow.” Once you start paying attention to how work actually moves through the building, it’s impossible to unsee the patterns. Someone steps around a broken pallet and adds a tiny hip twist they’ll repeat a few hundred times a day. Another person pauses to lift a box that technically weighs less than a bowling ball but is shaped to fight them every inch of the way. These details tend to hide in plain sight, but they are the real influencers of strain and fatigue.

Culture Matters More Than Checklists

A warehouse ergonomics program only sticks when the people doing the work feel like they have the right to speak up about discomfort before it becomes an injury report. That means building a culture where saying “this task feels off” is normal instead of annoying. Supervisors who take two minutes to watch someone’s process instead of brushing off concerns usually end up spotting things that engineers and outsiders miss. It’s less about formal audits and more about casual curiosity. When the mindset shifts from compliance to collaboration, people start catching risks long before they become trends on a dashboard.

Equipment Is Only Helpful If It Matches Reality

It’s easy to buy a shiny new device that promises to eliminate half of your lifting exposure. It’s harder to make sure the thing actually fits the workflow. Tools that require extra steps or feel awkward get abandoned faster than you can host the training sessions. The equipment that works tends to blend into the flow, almost like it was always part of the job. Pallet jacks with intuitive handles, lift tables that don’t fight people, carts that roll because their wheels aren’t fossilized in dust. The small stuff often carries more weight than the expensive showpieces.

A Program That Grows as the Warehouse Changes

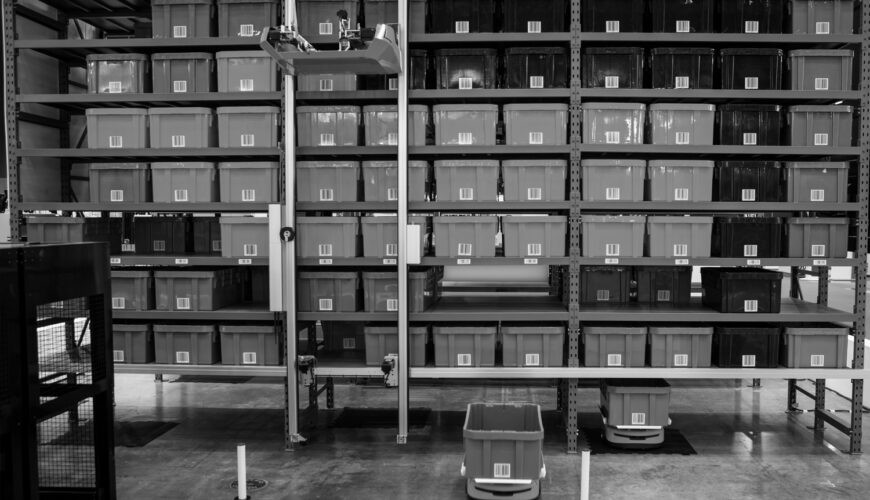

Warehouses don’t sit still. New product lines show up, aisles get rearranged, volume swings in whatever direction the season demands. A warehouse ergonomics program that’s built once and filed away turns irrelevant pretty quickly. The stronger approach is treating ergonomics like an ongoing conversation, not a one-time project. Every layout change, every shift in order profiles, every new piece of racking is a chance to re-evaluate how humans are moving through the space. When the program grows along with the building, you don’t end up playing catch-up after someone gets hurt.

The Human Side of Efficiency

People sometimes talk about warehouse ergonomics like it’s a wellness perk, but in warehouses it’s inseparable from throughput. Tired, uncomfortable workers slow down. Workers who can move comfortably and predictably keep the rhythm of the building intact. Good ergonomics isn’t about coddling anyone; it’s about respecting the reality that the human body sets limits, and ignoring those limits eventually costs more time and money than designing work that fits people. When someone feels better at the end of the day, odds are the warehouse ran better too.

Beyond the Bench and Into the Flow

Designing warehouse ergonomics beyond workstations isn’t really about complexity—it’s about honesty. The real work happens on the move, between tasks, in awkward corners, and in repetitive motions people stop thinking about. A program that acknowledges that, follows the workflow, and listens to the people doing the job will always outperform one that stays boxed in at the station.

Once ergonomics becomes part of the everyday conversation, the warehouse starts working with the people instead of against them, and that’s when everything gets easier.