In today’s volatile global marketplace, the sustainability of supply chain networks is under constant threat. Some experts argue that rapid supply chain evolution means that many systems are only truly effective for about 12 months before becoming outdated. While this may seem extreme, most logistics professionals agree, planning for only one year severely limits the potential return on investment in infrastructure, systems, people, and processes.

So, the real challenge isn’t whether supply chains expire, it’s how to manage uncertainty while maintaining the foresight required for service-level commitments and cost controls. Agility, flexibility, scalability, and the ability to adapt to continuous disruption are now baseline requirements. Recent swings in fuel prices, equipment shortages, and capacity issues across ports and rail systems highlight the dangers of planning with yesterday’s data.

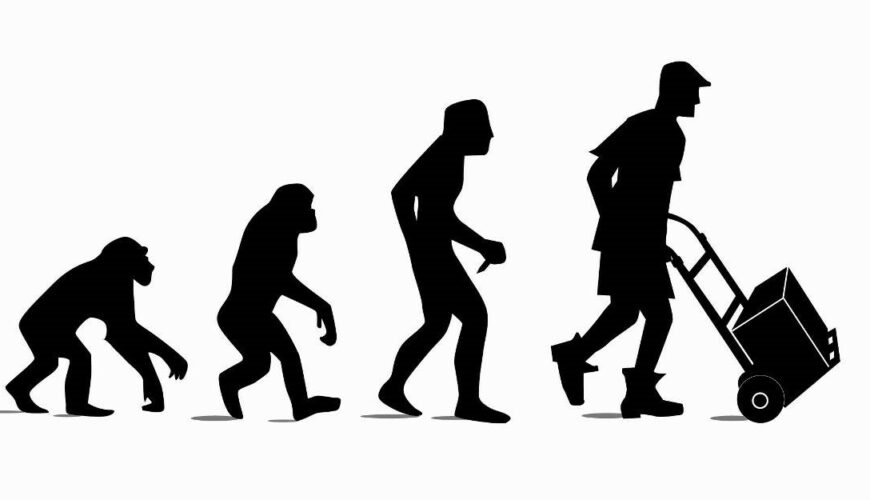

The Supply Chain Evolution Analogy

Just as species in the rainforest compete for limited resources, companies battle over finite market opportunities. In both ecosystems, survival favors those who are strongest, most adaptable, and most strategic. Darwin’s theory applies as much to global business as it does to biology; only the most fit will endure.

Flawed From the Start: The Supply Chain DNA Problem

Many supply chain designs are flawed from inception. The standard method involves gathering historical data and layering it with growth projections to create a design-year plan, typically with a five-year horizon. Shorter timelines don’t justify investment, while longer ones become too speculative. But when you multiply outdated data by unreliable forecasts and then let the plan sit idle during 9 to 24 months of construction or retrofitting, the result is a blueprint rooted in assumptions, not reality.

This flawed foundation is common practice, even though it’s equivalent to saying: “Multiply old data by guesswork and then wait to use it.” Despite how risky that sounds, it’s how most optimization projects begin.

The 3PL Trap

This unpredictability often pushes companies toward third-party logistics (3PL) providers for flexibility. But 3PLs face the same visibility issues. Their contracts are typically short-term and costly. Without long-term volume commitments, they can’t invest in automation or advanced infrastructure. As a result, both in-house and outsourced operations tend to fall back on labor-heavy processes, which are less efficient and rarely deliver the performance needed to stay competitive.

Corporate Darwinism Is Real

Change is inevitable. The supply chain evolution has accelerated dramatically. Survival now hinges on your ability to adapt. Companies that resist change face rapid failure. Those who merely react to it are constantly playing catch-up. But those who anticipate and lead change gain a real advantage.

Forget about achieving a fully “optimized” supply chain; that’s an illusion. The target keeps moving. What matters is staying closer to optimization than your competitors. The performance gap between your supply chain and what’s possible, your Operations Performance Gap (OPG), becomes a weapon competitors can and will use against you. A small OPG might be manageable if brand strength and marketing are robust. But a wide OPG is an open invitation for disruption and defeat.

Continuous Supply Evolution Through “What-If” Thinking

Survival demands continuous improvement and constant reevaluation. One of the most powerful tools is scenario planning, stress-testing your supply chain with “what if” questions:

- What if fuel prices spike again?

- What if customer orders shift to smaller, more frequent shipments?

- What if parcel replaces LTL?

- What if we transition to on-demand production?

- What if inventory levels are cut in half?

Answering these questions, both individually and in combination, helps reduce uncertainty and prepares the unknown.

Rewriting the Genetic Code

In biology, genetic engineering modifies an organism’s DNA to improve its survival. In supply chain management, our “DNA” is the logic behind systems design, operational processes, and infrastructure. And like scientists testing genetic outcomes in a lab, supply chain professionals can use simulation modeling to test different designs before implementation.

Simulation modeling creates a virtual replica of a real or conceptual supply chain. Once validated, it allows professionals to manipulate variables and test performance under various conditions, identifying bottlenecks, testing throughput, and gauging resilience before a single dollar is spent on physical assets.

Modern simulation tools go further by providing high-quality 3D animations, helping decision-makers visualize how a system performs. While the real insights come from statistical analysis, these visuals can be critical in aligning executive leadership around complex solutions.

The Final Word: Evolve or Become Extinct

Regardless of your industry, an agile, flexible, and scalable supply chain is no longer optional; it’s foundational. Those that build tightly integrated, continuously improving operations with a focus on execution will thrive. Those who cling to outdated models will fall behind.

The market will always favor the organizations that evolve faster, plan better, and execute with precision. In the end, it’s not about who is best today, it’s about who is best prepared for tomorrow.