How many distribution centers (DCs) should your company operate? Where should they be located? How large should each facility be, what inventory should reside in each, and which customers should be serviced from where? What ports of entry and transportation modes should you rely on?

These are not theoretical questions—they’re central to how well your supply chain performs. And in 2025, with higher operating costs, tighter service expectations, and continued global volatility, companies must answer them with precision.

Yet the right answers vary widely from business to business—even within the same industry. Unique product characteristics, customer locations, service-level agreements, and inherited infrastructure all influence what an “optimal” network looks like. Often, companies are operating with outdated or sub-optimal networks that no longer match demand patterns or logistics realities. This makes network rationalization a necessary exercise, not a discretionary one.

A Structured Approach to Network Design

Network rationalization is the process of evaluating your current distribution structure to determine whether it still aligns with your business goals—and if not, how it should be redesigned. It involves a comprehensive analysis of:

- Facility count, location, and utilization

- Customer proximity and service performance

- Inventory positioning

- Transportation cost and carrier usage

- Trade routes, ports of entry, and delivery modes

The objective is not just cost reduction. Rationalization ensures that physical infrastructure supports service goals, minimizes risk, and remains adaptable to future changes in demand, sourcing, or regulation.

Center-of-Gravity Modeling: Finding the Right Locations

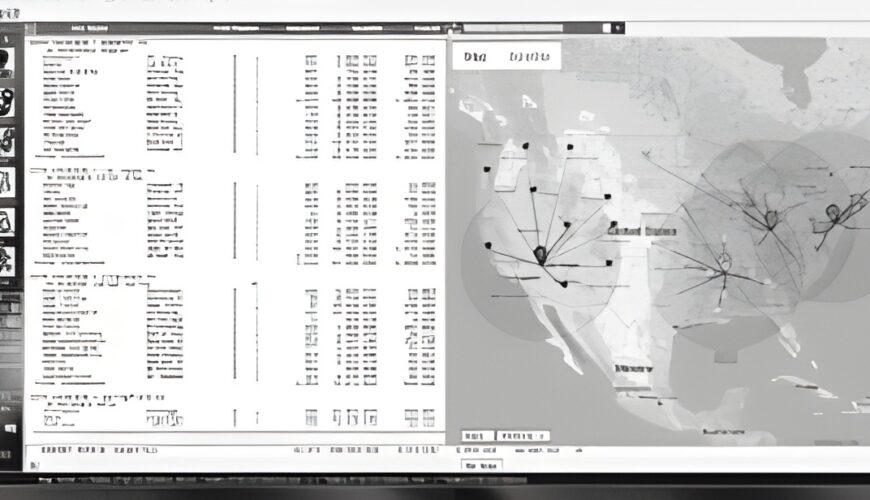

At the core of this analysis is geographic center-of-gravity modeling—a method that identifies the ideal number and placement of DCs by analyzing the weighted cost and volume of inbound supply and outbound demand. These models simulate different distribution configurations to help determine:

- Where DCs should be located to minimize distance and cost

- What inventory should be stored at each facility

- Which customers should be served from which node

- How transportation cost and service levels vary by scenario

Unlike static location decisions based on real estate availability or legacy positioning, center-of-gravity modeling provides a clear, data-driven foundation for long-term network design.

Balancing Cost, Service, and Risk

As with any supply chain engineering initiative, location modeling requires balancing competing priorities. Most notably, there is an inherent trade-off between transportation cost and inventory cost. Fewer, larger DCs can reduce inventory but increase last-mile shipping costs and delivery time. More, smaller facilities may improve responsiveness but increase holding costs and complexity.

These trade-offs extend beyond cost. Companies must weigh:

- Speed vs. consolidation

- Flexibility vs. overhead

- Resilience vs. efficiency

- Short-term savings vs. long-term scalability

That’s why the goal isn’t simply to find the lowest-cost network—but the most effective one that aligns with your broader strategic objectives.

The Role of Sensitivity Analysis

Even the best-designed network models are only as good as the assumptions behind them. In today’s volatile landscape, critical variables—fuel prices, labor rates, tariffs, port congestion, and environmental regulations—can shift unexpectedly.

To account for this, companies must conduct sensitivity analysis, testing each network configuration under multiple “what-if” scenarios. This helps identify designs that are not just efficient in stable conditions, but resilient in times of disruption. It’s common to find several network alternatives that deliver similar cost and service results—yet only one may sustain performance when conditions deteriorate.

From Modeling to Action: Why Network Rationalization Matters Now

Many supply chains were built for a different era—when customer expectations were slower, labor was more plentiful, and transportation costs were lower. Holding on to outdated networks leads to inflated costs, lagging service levels, and diminished competitiveness.

Rationalizing your distribution network—backed by geographic modeling and grounded in real-world constraints—ensures that your supply chain is positioned for both today’s demands and tomorrow’s disruptions.

How OPSdesign Consulting Can Help

OPSdesign Consulting partners with companies to evaluate, model, and redesign their supply chain networks using proven methodologies. Our services include:

- Mapping and analysis of your current supply chain network, cost structure, and service performance

- Geographic center-of-gravity modeling to identify ideal DC locations, inventory strategies, and customer assignments

- Transportation and logistics scenario modeling

- Sensitivity testing across variables such as fuel, port congestion, and labor availability

- Comparative analysis of viable future-state network alternatives

OPSdesign Consulting can map your existing supply chain network, service, and cost structure; build computer models of viable alternatives, and perform a comparative analysis to determine the one that best meets your corporate goals and objectives.