Designing a new warehouse operation requires a systematic approach that considers processes, systems, infrastructure, and labor optimization. This can be achieved through industrial engineering methodologies.

Here are the steps for designing a new warehouse operation:

1. Project Initiation:

- Define Project Objectives: Clearly articulate your goals and objectives when designing a new warehouse. Determine what you aim to achieve, such as increasing efficiency, reducing costs, or improving order accuracy.

- Assemble a Project Team: Create a cross-functional team that includes industrial engineers, logistics experts, IT specialists, and key stakeholders from various departments.

2. Data Collection and Analysis:

- Gather Existing Data: Collect data on current warehouse operations, including inventory levels, order volumes, SKU information, and historical performance data.

- Analyze Data: Utilize industrial engineering techniques to analyze the collected data. Techniques may include time-motion studies, process flow analysis, and statistical analysis to identify bottlenecks, inefficiencies, and areas for improvement.

3. Process Mapping:

- Map Current Processes: Create detailed process maps that illustrate the flow of goods within the warehouse. Identify key processes such as receiving, put away, picking, packing, and shipping.

- Identify Pain Points: Highlight areas where processes are suboptimal or where inefficiencies exist. Consider factors such as travel distances, picking methods, and order consolidation.

4. Systems Evaluation:

- Inventory Management Systems: Assess the existing or proposed inventory management system. Consider whether it can support real-time tracking, demand forecasting, and SKU optimization.

- Warehouse Management System (WMS): Evaluate the suitability of the WMS for your specific needs. Ensure it can efficiently manage order fulfillment, inventory control, and labor allocation.

- Automation and Technology: Explore options for warehouse automation, including conveyor systems, robotics, and RFID technology. Assess their feasibility and ROI.

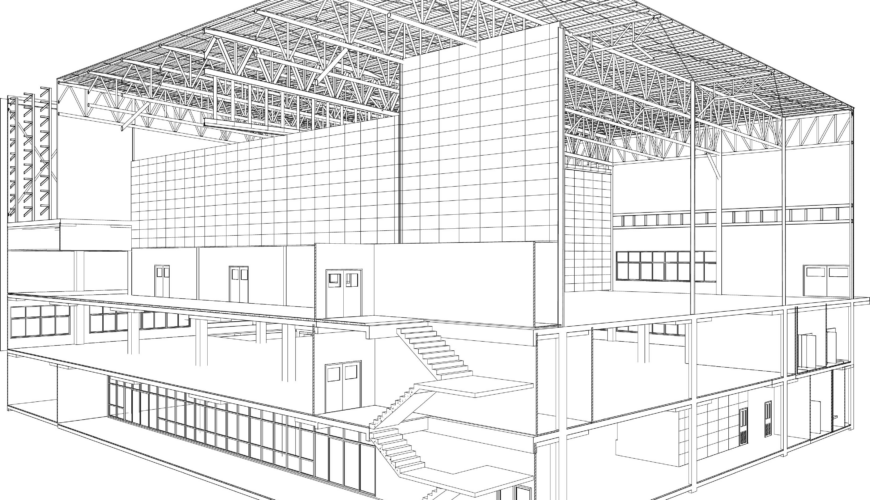

5. Infrastructure Planning:

- Warehouse Layout: Develop warehouse layout options that optimize space utilization and material flow. Consider factors like racking systems, aisle widths, and storage density.

- Material Handling Equipment (MHE): Determine the type and quantity of MHE required. Evaluate the feasibility of using forklifts, automated guided vehicles (AGVs), or other equipment.

- Facility Design: Consider factors such as lighting, ventilation, safety features, and compliance with local building codes and regulations.

6. Labor Optimization:

- Workforce Analysis: Analyze current labor requirements and skill levels. Consider factors like workforce capacity, shift scheduling, and labor allocation.

- Labor Training: Plan for employee training programs to ensure that workers can operate new equipment and systems effectively.

7. Simulation and Modeling:

- Warehouse Simulation: Use industrial engineering software to create warehouse simulations. Simulate various design scenarios to assess their impact on efficiency, throughput, and resource utilization.

8. Comparative Analysis:

- Scenario Comparison: Compare different design scenarios based on key performance indicators (KPIs) such as order fulfillment time, labor productivity, inventory turnover, and operating costs.

- Cost-Benefit Analysis: Evaluate the cost-effectiveness of each scenario, considering both initial implementation costs and long-term operational savings.

9. Design Optimization:

- Iterative Design: Refine the warehouse design based on the findings from the comparative analysis and feedback from the project team.

- Risk Assessment: Identify potential risks and mitigation strategies associated with the chosen design.

10. Implementation Planning:

- Phased Implementation: Develop a phased implementation plan to minimize disruptions to ongoing operations. Determine the sequence in which changes will be made.

- Resource Allocation: Allocate resources, including budget, personnel, and equipment, for the implementation phase.

11. Testing and Validation:

- Pilot Testing: Conduct pilot testing of the new warehouse design with a limited scope of operations to identify and resolve any unforeseen issues.

- Validation: Validate that the new design meets the predefined objectives and KPIs.

12. Documentation:

- Documentation and Manuals: Create comprehensive documentation and operation manuals for the new warehouse processes, systems, and equipment.

13. Training:

- Employee Training: Provide training to warehouse staff on new processes, equipment, and systems.

14. Go-Live:

- Full Implementation: Transition to the new warehouse design and operations. Monitor performance closely during the initial period.

15. Continuous Improvement:

- Post-Implementation Review: Conduct a post-implementation review to assess the performance of the new warehouse design and identify areas for further optimization.

- Ongoing Monitoring: Continuously monitor KPIs and make adjustments as needed to maintain and improve warehouse efficiency.

By following these steps and leveraging industrial engineering principles when designing a new warehouse, you can systematically design and optimize a new warehouse operation for maximum efficiency, productivity, and cost-effectiveness while minimizing risks and disruptions. Contact OPSdesign before Designing a new warehouse!