Discover Opportunities to Add Value, Reduce Costs, Assure Quality, and Compress Time™

Staying ahead of the curve in supply chain operations requires constant evaluation and optimization. This need for continuous improvement is magnified during times of change, such as mergers, acquisitions, new product lines, growing SKUs, distribution network adjustments, and new market channels, such as e-commerce.

To navigate this dynamic terrain effectively, companies often turn to operational audits to assess their performance and identify areas for improvement.

OPSdesign Consulting’s engineering (new facilities) or re-engineering (retrofits) initiatives employ an industrial engineering-based methodology encompassing four key project phases: Discovery, Strategy, Planning, and Implementation. This article explores the significance of operational audits, which fall under the Discovery Phase.

This initial phase serves as the foundation for subsequent optimization work, while Strategy, Planning, and Implementation services are deferred until the completion of the Discovery Phase. This approach ensures a thorough understanding of the operational landscape before devising optimal processes, systems, infrastructure, and labor alternatives.

Defining Your Place on the Operational Continuum

At the heart of an operational audit lies the identification of performance gaps between current practices and industry standards. We call that an Operations Performance Gap (OPG)™. By conducting a high-level assessment, companies can gain valuable insights into potential opportunities for enhancement. Our approach is rooted in defining where an organization stands on the operational continuum, providing a strategic and tactical roadmap for future operational optimization.

Leveraging the Scorecard Tool

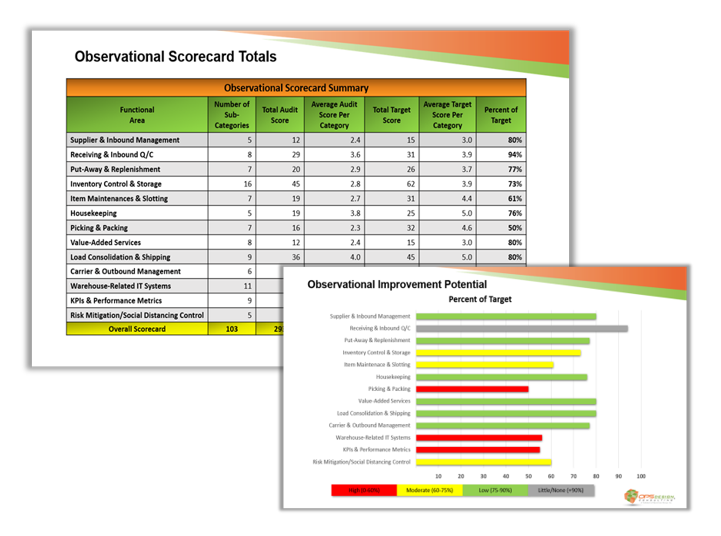

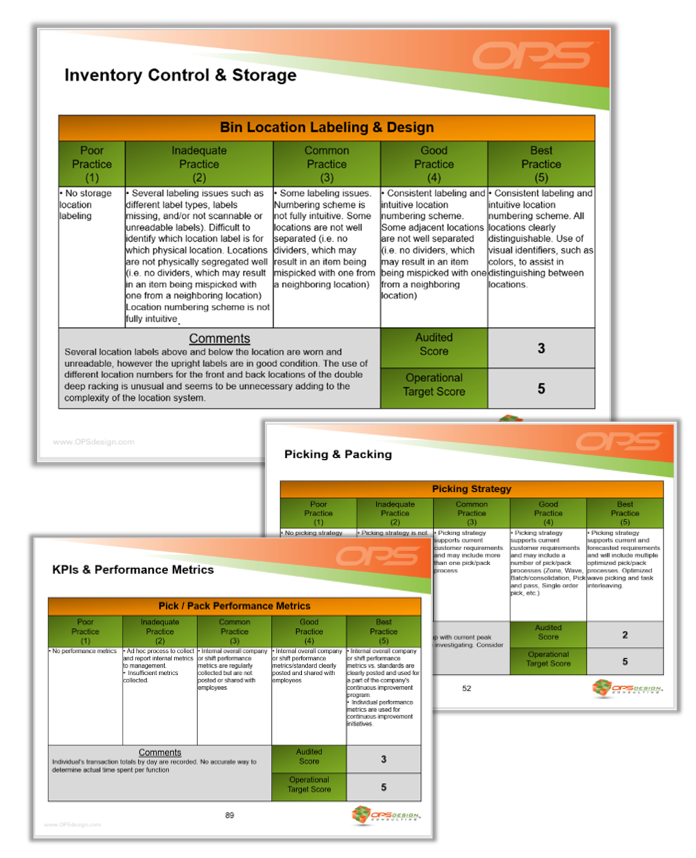

A cornerstone of OPSdesign’s operational audit is the utilization of its operational scorecard. This evaluative matrix aids in defining an operation’s improvement potential across various dimensions, including process, systems, infrastructure, and labor strategy. With 90 subjectively scored operational attributes distributed among thirteen functional areas, the scorecard offers a holistic view of an organization’s strengths and areas for improvement.

- Supplier & Inbound Management

- Receiving & Inbound Q/C

- Put-Away & Replenishment

- Inventory Control & Storage

- Item Maintenance & Slotting

- Housekeeping

- Picking & Packing

- Value-Added Services

- Load Consolidation & Shipping

- Carrier & Outbound Management

- Warehouse-Related IT Systems

- KPIs & Performance Metrics

- Risk Mitigation/Social Distancing Control

Each functional area has several sub-categories with a rating scale of poor practice (1) to best practice (5). Based on the attributes of a best practice scale, OPSdesign Consultants and Engineers assign a target score from 1 to 5 for each sub-category, as best practice may not be beneficial for all operations. Each functional area is assigned an overall score of one of four categories: high, moderate, low, or little/no improvement potential.

Collaborative Assessment for Improvement

Central to OPSdesign’s approach is positive and constructive collaboration with management and staff. By fostering an open dialogue and cooperation environment, OPSdesign aims to identify and assess opportunities for operational enhancement collaboratively. Recognizing that all operations are works in progress, the focus is on facilitating meaningful improvements while acknowledging the constraints faced by operational teams. Over time, all operations are subject to the proverbial application of “Band-Aids®, bubble gum, and duct tape” to fight the fire of the day and get orders out the door. These efforts are heroic and necessary. However, this natural evolution often leads to layers of patches and quick fixes, which result in a sub-optimal operation.

Charting the Path Forward

The operational audit’s culmination is a concise gap analysis between the current state, industry benchmarks, and best practices. This examination serves as a springboard for developing a plan of action to perform detailed data analysis, comparative analysis of alternatives (process, systems, infrastructure, and labor), and design detailing of the most favorable solutions.

Conclusion

In today’s competitive landscape, warehouse operations audits play a pivotal role in identifying performance gaps and driving continuous improvement. OPSdesign’s meticulous approach to operational audits empowers organizations to navigate the complexities of warehouse management effectively. By leveraging insights gleaned from assessments and fostering collaborative partnerships, companies can chart a course toward operational excellence, ensuring sustainable growth and success in the long run.

Call us at 856-797-1933 or email info@OPSdesign.com and ask us about working as part of your team on a Warehouse Operations Audit.