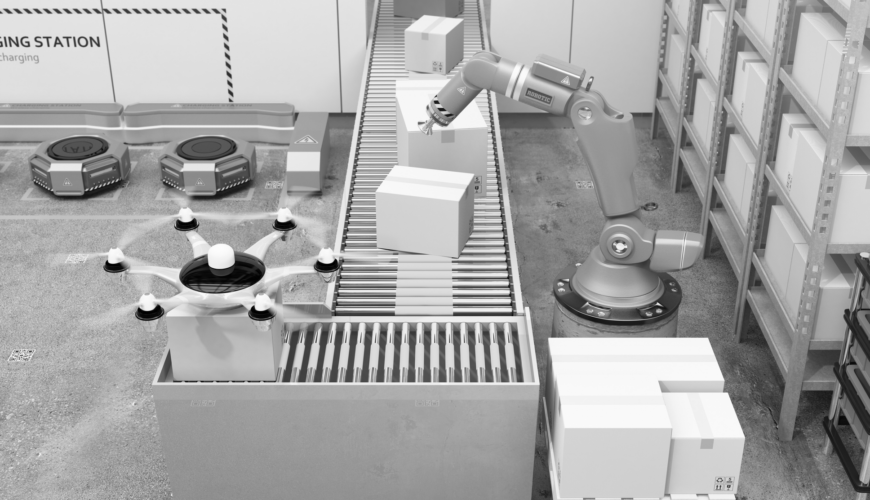

Companies are using warehouse mechanization, automation, robotics, and artificial intelligence (AI) to enhance efficiency, productivity, and competitiveness. However, adopting these technologies requires careful consideration and planning to ensure alignment with the operation’s specific needs and goals. This article provides a comprehensive guide for decision-making, offering a checklist of key points to consider when contemplating the implementation of warehouse mechanization, automation, robotics, and AI.

10 Ways Warehouse Mechanization Benefits Your Business

Current Operational Challenges

Begin by identifying the existing challenges and pain points within the warehouse operation. Consider factors such as labor shortages, inefficient processes, inaccuracies in inventory management, and fulfillment delays. Assess the extent to which mechanization, automation, robotics, and AI can effectively address these challenges.

Cost-Benefit Analysis

Conduct a thorough cost-benefit analysis to evaluate the financial implications of implementing these technologies. Consider upfront investment costs, ongoing maintenance expenses, and potential cost savings in labor, time, and operational efficiency. Determine the return on investment (ROI) period and weigh it against the long-term benefits.

Scalability and Flexibility

Assess the scalability and flexibility of the chosen technologies to accommodate future growth and changes in operational requirements. Consider whether the systems can adapt to fluctuations in demand, seasonal variations, and evolving market trends. Evaluate the ease of reconfiguration and expansion to meet changing needs.

Integration with Existing Systems

Evaluate the compatibility of mechanization, automation, robotics, and AI solutions with existing warehouse management systems (WMS) and other technology infrastructure. Ensure seamless integration to minimize disruption to ongoing operations and data integrity. Consider the need for additional software development or customization to achieve optimal integration.

Technological Maturity and Reliability

Assess the maturity and reliability of the chosen technologies, considering factors such as reliability, accuracy, and uptime. Evaluate the track record of vendors and manufacturers in delivering robust solutions with proven performance. Seek references and testimonials from other organizations that have implemented similar technologies.

Employee Impact and Training

Consider the impact of mechanization, automation, robotics, and AI on the existing workforce. Evaluate the potential for job displacement and the need for retraining or upskilling employees to adapt to new roles. Communicate transparently with employees about the rationale behind the technology adoption and provide support during the transition.

Regulatory Compliance and Safety

Ensure compliance with relevant regulatory requirements and safety standards governing the operation of mechanized and automated systems. Assess the potential risks associated with robotics and AI, such as collisions, equipment malfunction, and data security breaches. Implement robust safety protocols, training programs, and risk mitigation strategies to minimize potential hazards.

Performance Metrics and Monitoring

Define key performance indicators (KPIs) to measure the impact of warehouse mechanization, automation, robotics, and AI on operational efficiency and effectiveness. Establish a system for real-time monitoring and reporting to track progress towards goals and identify areas for improvement. Use data analytics and machine learning algorithms to optimize decision-making and process optimization.

Customer Experience and Satisfaction

Consider the impact of technology adoption on the overall customer experience and satisfaction levels. Evaluate whether faster order fulfillment, accurate inventory tracking, and seamless logistics operations can enhance customer loyalty and retention. Solicit feedback from customers and stakeholders to gauge satisfaction with the implemented technologies.

Environmental Sustainability

Assess the environmental impact of warehouse mechanization, automation, robotics, and AI on energy consumption, emissions, and resource utilization. Explore opportunities for eco-friendly solutions, such as energy-efficient equipment, recyclable materials, and optimized transportation routes. Align technology adoption with corporate sustainability goals and initiatives to minimize the ecological footprint.

Deciding whether warehouse mechanization, automation, robotics, and artificial intelligence are right for your operation requires a comprehensive evaluation of various factors, ranging from operational challenges and cost considerations to employee impact and regulatory compliance. By following the checklist in this article, organizations can make informed decisions that align with their strategic objectives and position them for success in an increasingly competitive marketplace. Ultimately, embracing these transformative technologies can unlock new opportunities for efficiency, productivity, and innovation in warehouse operations.