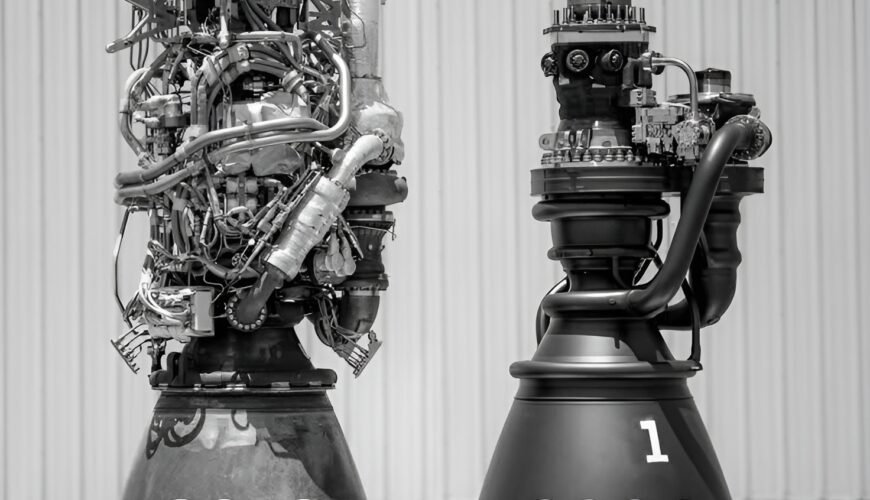

The SpaceX Raptor engines (Raptor 1 and Raptor 3) are designed for spaceflight, particularly for the Starship and Super Heavy launch system. The Raptor engines are notable for being a fully reusable, next-generation engine powered by liquid methane and liquid oxygen (methalox). While Raptor 1 and Raptor 3 are part of this family, there are significant differences.

Raptor 1

- Development Stage: Raptor 1 was SpaceX’s first version of the Starship program, designed for testing and early flights.

- Thrust: In its full configuration, the Raptor 1 generates around 200 tons (2000 kN) of thrust.

- Design Focus: Raptor 1 was primarily designed to test the new methalox engine technology, including the performance of the methane and liquid oxygen propellants. It served as the foundation for further development of the engine.

-

Key Features:

- It used a full-flow staged combustion cycle, a sophisticated and efficient approach to engine design.

- The engine was built for reusability, but its design was still evolving, with many of the key features being refined in later versions.

Raptor 3

- Development Stage: The Raptor 3 is the third major iteration in the Raptor engines series and represents a significant advancement in performance, efficiency, and design from the Raptor 1.

- Thrust: Raptor 3 is expected to generate approximately 230-250 tons (2300-2500 kN) of thrust, making it significantly more powerful than Raptor 1.

- Design Focus: The Raptor 3 is optimized for higher efficiency, greater reusability, and better manufacturing processes. SpaceX has implemented several design changes to improve the engine’s performance and reduce costs per flight.

-

Key Features:

- Improved Chamber Pressure: Raptor 3 operates at a higher chamber pressure than Raptor 1, leading to more thrust and efficiency.

- Enhanced Reusability: The Raptor 3 includes improvements in durability and reusability, which are crucial for reducing the cost of space travel, as it is designed to be rapidly refurbished and reused.

- Simplified Design: SpaceX significantly improved the manufacturing process, reducing the number of parts and simplifying the design to improve scalability and reduce production costs.

Key Differences

- Thrust: Raptor 3 provides significantly more thrust (around 2300-2500 kN) than Raptor 1 (around 2000 kN).

- Efficiency and Performance: Raptor 3 is more efficient with a higher chamber pressure and improved fuel efficiency, increasing its overall performance.

- Manufacturing and Cost: Raptor 3 incorporates lessons from Raptor 1 and 2, including better production techniques to lower costs and speed manufacturing.

- Reusability: Both engines are designed with reusability in mind, but Raptor 3 has been designed with improved durability for rapid reuse.

In essence, Raptor 3 represents the latest and most refined iteration of SpaceX’s next-generation engine, with increased power, efficiency, and reusability compared to Raptor 1, a critical early step in developing the Starship system. The photo above tells a compelling story about the power of simplification and advanced engineering.