An efficient warehouse design directly impacts customer satisfaction, operational costs, and overall competitiveness. In the world of modern logistics, speed and accuracy are the cornerstones of success. Whether managing a small e-commerce fulfillment center or a large distribution hub, Today’s warehouses must blend smart layout planning, advanced technology, and well-trained staff to achieve seamless order fulfillment.

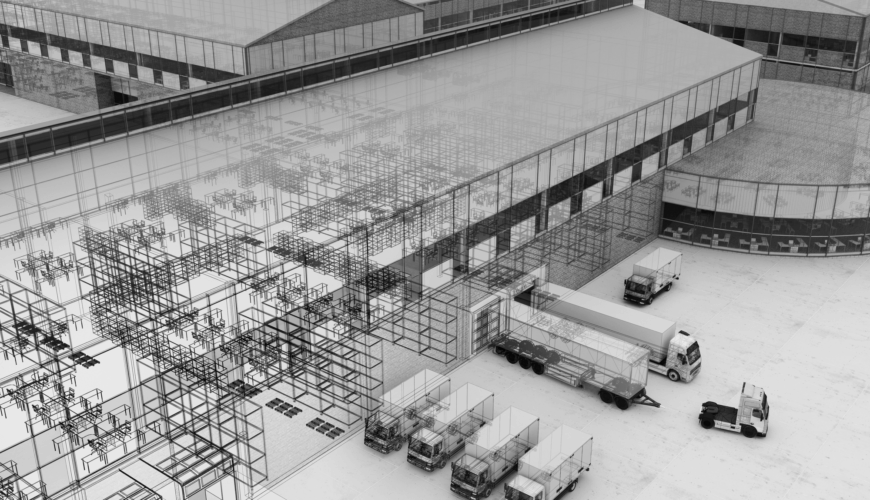

Floor Plans for Efficient Warehouse Design

The foundation of a high-performing efficient warehouse design begins with its floor plan. A well-designed floor plan reduces travel time, minimizes congestion, and ensures products move quickly from storage to shipping. Placing fast-moving, high-demand items closer to the packing and shipping stations can dramatically cut down on picker travel time. Additionally, establishing clear, one-directional pick paths reduces backtracking and confusion, keeping workflows smooth and predictable. Many operations now employ zone picking, dividing the warehouse into specific areas where multiple pickers work simultaneously to fulfill different parts of an order, ultimately increasing throughput and reducing delays.

Smarter Inventory Management

Accurate, responsive inventory management is vital for shipping speed and precision. Modern systems use ABC analysis to prioritize space and handling for high-turnover “A” items, ensuring that frequently ordered products are always within quick reach. For perishable or time-sensitive goods, the First-In-First-Out (FIFO) approach remains essential, preventing product aging or spoilage. Regular cycle counting, small, frequent audits of specific inventory sections, helps maintain accurate stock records and prevents costly fulfillment errors before they occur.

Leveraging Technology and Automation

Technology continues to reshape how warehouses operate. A robust Warehouse Management System (WMS) serves as the operational nerve center, orchestrating inventory tracking, optimizing pick routes, and providing real-time visibility into stock levels. Coupled with barcode and RFID scanning, these tools reduce human error and speed up the picking and packing process.

For larger operations, automation and robotics are increasingly practical. Automated conveyors, autonomous mobile robots (AMRs), and robotic picking systems not only accelerate order handling but also improve accuracy and consistency. Even moderate investments in automation can yield substantial gains in efficiency.

Investing in Employee Training

Despite automation, skilled employees remain irreplaceable in ensuring shipping accuracy and safety. Continuous training in order picking techniques, equipment operation, and quality control protocols enhances both productivity and workplace safety. Empowered employees who understand the importance of precision are more likely to spot errors early and maintain the high standards customers expect.

Streamlining Packaging Processes

Packaging represents a key opportunity to boost efficiency while protecting products and the environment. Standardized packaging materials simplify decisions and speed up assembly, while automated packaging systems can measure, cut, and seal boxes with remarkable accuracy and speed. Today’s sustainable packaging options, biodegradable fillers, right-sized boxes, and recyclable materials also reduce waste and shipping costs while aligning with consumer expectations for environmental responsibility.

Harnessing Data for Continuous Improvement

Modern efficient warehouse design thrives on data. By analyzing performance metrics such as order accuracy, fulfillment time, and on-time delivery rates, managers can pinpoint inefficiencies and target improvements. Predictive analytics and demand forecasting help allocate resources effectively, reduce bottlenecks during peak periods, and improve inventory planning. When issues arise, root cause analysis ensures that problems are addressed systematically rather than repeatedly patched over.

Building a Culture of Continuous Optimization

Efficient warehouse design is not a one-time project; it’s an evolving system. Continuous improvement requires regular review of processes, employee feedback, and adaptability to technological advancements. The most successful operations embrace change, experimenting with new layouts, tools, and methods to stay agile in an ever-faster marketplace.

In conclusion, achieving faster and more accurate shipping is the result of thoughtful and efficient warehouse design that integrates layout optimization, technology, skilled staff, and data-driven decision-making. By continually refining these components, businesses can reduce costs, delight customers, and stay competitive in a logistics landscape that rewards both speed and precision.