In the modern industrial and supply chain environment, organizations continuously seek ways to improve operational efficiency, reduce waste, and enhance product and service quality. To achieve these goals, several proven methodologies have emerged over the decades, each with its own framework, tools, and ideal use case. Among the most prominent are Six Sigma, 5S, and Lean. Additionally, complementary and overlapping methodologies such as Kaizen, Total Productive Maintenance (TPM), and the Theory of Constraints (TOC) offer further opportunities for targeted improvements.

This white paper explores the fundamental concepts of these methodologies, compares their respective strengths and limitations, and outlines the operational circumstances under which each is most advantageous.

Definitions and Origins

Six Sigma

Definition:

Six Sigma is a data-driven methodology focused on improving quality by identifying and eliminating defects and minimizing variability in processes. Its primary objective is to achieve near-perfection, measured statistically as no more than 3.4 defects per million opportunities (DPMO).

Origin:

Developed by Motorola in the 1980s and later popularized by General Electric, Six Sigma integrates statistical tools and project management practices into a structured problem-solving approach.

Core Methodologies:

- DMAIC (Define, Measure, Analyze, Improve, Control) – used for improving existing processes.

- DMADV (Define, Measure, Analyze, Design, Verify) – used for creating new processes or products.

Key Concepts:

- Voice of the Customer (VOC)

- Critical to Quality (CTQ) characteristics

- Process Capability (Cp, Cpk)

- Root Cause Analysis (RCA)

- Statistical Process Control (SPC)

5S

Definition:

5S is a workplace organization and housekeeping methodology designed to improve efficiency, reduce waste, and ensure a clean and safe environment. It is often the first step in Lean implementation.

Origin:

Rooted in Japanese manufacturing culture, particularly the Toyota Production System (TPS), 5S stands for five Japanese terms that start with “S”:

- Seiri (Sort) – Remove unnecessary items.

- Seiton (Set in Order) – Organize remaining items.

- Seiso (Shine) – Clean the workspace.

- Seiketsu (Standardize) – Establish standards for the above steps.

- Shitsuke (Sustain) – Maintain and review standards.

Benefits:

- Improved safety

- Increased productivity

- Reduced waste

- Enhanced visual management

Lean

Definition:

Lean is a systematic approach to identifying and eliminating non-value-added activities (waste) through continuous improvement and respect for people. Its goal is to deliver customer value with the least amount of resources.

Origin:

Developed from the Toyota Production System, Lean manufacturing was formalized in the 1990s through the work of Womack and Jones in “The Machine That Changed the World.”

Core Principles:

- Identify value.

- Map the value stream.

- Create flow.

- Establish pull.

- Pursue perfection.

Types of Waste (Muda):

- Overproduction

- Waiting

- Transport

- Extra Processing

- Inventory

- Motion

- Defects

Kaizen

Definition:

Kaizen translates to “continuous improvement” and refers to small, incremental changes routinely made by employees to improve processes, reduce waste, and enhance quality.

Origin:

Japanese management philosophy widely adopted as part of Lean and TPS.

Tools and Practices:

- Kaizen Events or Blitzes

- Cross-functional teams

- Gemba walks

- Suggestion systems

Total Productive Maintenance (TPM)

Definition:

TPM aims to maximize the effectiveness of equipment by involving all employees in proactive maintenance activities and achieving zero breakdowns and zero defects.

Origin:

Developed in Japan and formalized by the Japan Institute of Plant Maintenance (JIPM).

Key Pillars:

- Autonomous Maintenance

- Planned Maintenance

- Quality Maintenance

- Focused Improvement

- Early Equipment Management

KPI Focus:

- Overall Equipment Effectiveness (OEE)

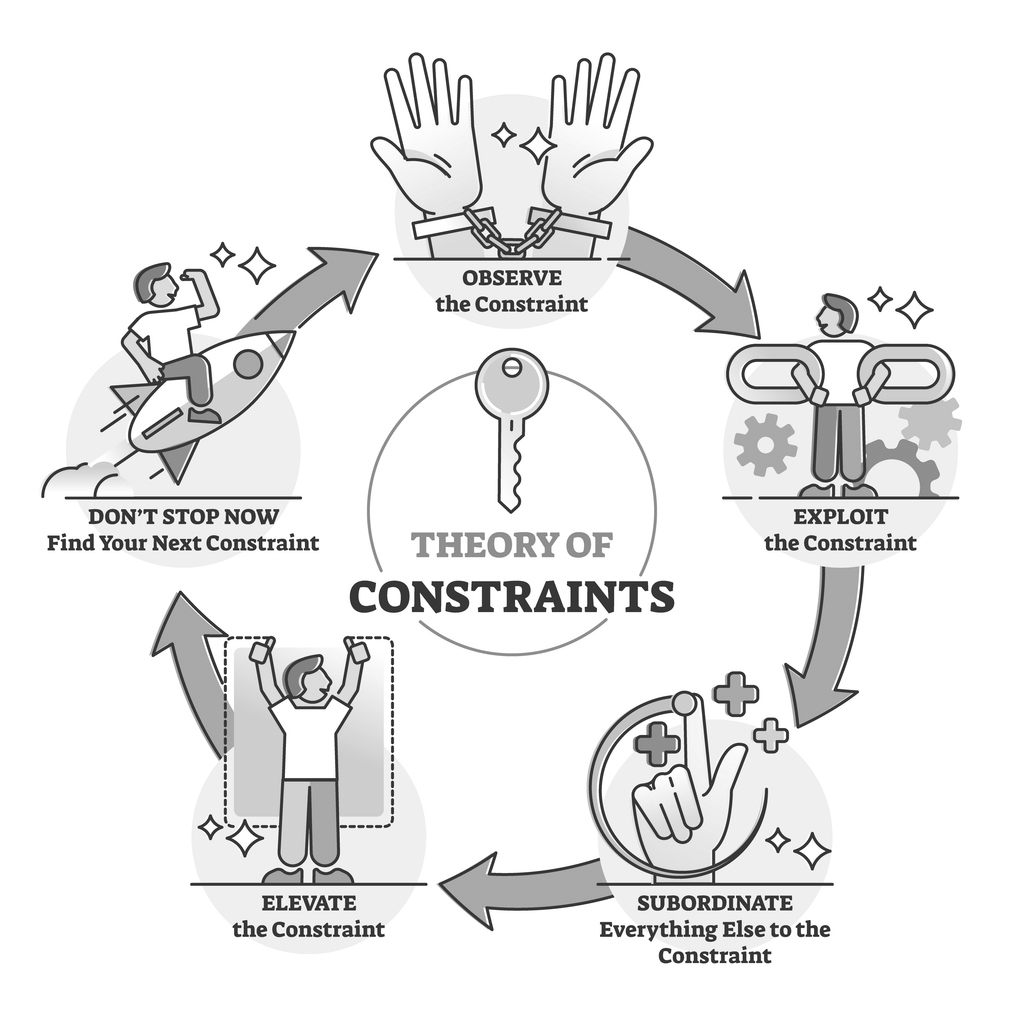

Theory of Constraints (TOC)

Definition:

TOC is a systems management philosophy that focuses on identifying the most critical limiting factor (constraint) in a process and systematically improving it until it is no longer the bottleneck.

Origin:

Developed by Dr. Eliyahu Goldratt and popularized through his book, “The Goal.”

Core Steps:

- Identify the constraint.

- Exploit the constraint.

- Subordinate everything else to the constraint.

- Elevate the constraint.

- Repeat the process.

Comparative Analysis

Six Sigma

• Primary Focus: Defect reduction and process variability

• Approach Type: Statistical, structured

• Key Metrics / Tools: DMAIC, SPC, DPMO, Root Cause Analysis

• Strengths: Enables data-driven decision-making and offers high precision in identifying and solving quality issues

• Best Used When: Improving quality in complex, data-rich processes where precision and control are critical

5S

• Primary Focus: Workplace organization

• Approach Type: Visual, procedural

• Key Metrics / Tools: 5S checklists, visual cues

• Strengths: Builds workplace discipline, enhances safety, and strengthens visual control systems

• Best Used When: Establishing a foundation for Lean initiatives or improving basic workplace efficiency and order

Lean

• Primary Focus: Waste elimination and value delivery

• Approach Type: Philosophical, operational

• Key Metrics / Tools: Value stream mapping, Kanban, Kaizen

• Strengths: Drives end-to-end process efficiency with a strong customer focus

• Best Used When: Streamlining entire processes to improve flow and eliminate non-value-adding activities

Kaizen

• Primary Focus: Continuous incremental improvement

• Approach Type: Cultural, team-based

• Key Metrics / Tools: Kaizen events, Gemba, PDCA (Plan-Do-Check-Act) cycle

• Strengths: Encourages employee involvement and fosters a culture of small, regular improvements

• Best Used When: Embedding a daily improvement mindset and boosting team engagement throughout the organization

TPM (Total Productive Maintenance)

• Primary Focus: Equipment uptime and reliability

• Approach Type: Preventive, operational

• Key Metrics / Tools: OEE (Overall Equipment Effectiveness), autonomous maintenance, structured checklists

• Strengths: Reduces equipment downtime and increases asset performance

• Best Used When: Operating in asset-heavy industries like manufacturing where equipment optimization is vital

TOC (Theory of Constraints)

• Primary Focus: Bottleneck and constraint management

• Approach Type: Systems-thinking

• Key Metrics / Tools: Five Focusing Steps, throughput analysis

• Strengths: Maximizes system throughput by identifying and managing constraints effectively

• Best Used When: Addressing performance issues caused by capacity limits or bottlenecks within a process

Advantages and Use Cases

Six Sigma: Best for Precision and Data-Intensive Quality Control

Advantages:

- Deep statistical rigor

- Structured problem solving (DMAIC)

- Defect and variation control

- High ROI for chronic quality issues

Ideal Use Cases:

- Transactional processes (e.g., finance, insurance)

- Manufacturing lines with persistent quality defects

- Highly regulated industries (e.g., pharmaceuticals, aerospace)

- Complex workflows with measurable outputs

Limitations:

- Can be bureaucratic

- Requires advanced training (Green Belt, Black Belt)

- May neglect speed and flow if applied in isolation

5S: Best for Foundational Workplace Discipline and Visual Management

Advantages:

- Quick implementation

- Engages frontline workers

- Enhances safety

- Foundation for Lean

Ideal Use Cases:

- Warehouses and distribution centers

- Shop floors

- Maintenance and repair operations (MRO)

- Start of any continuous improvement initiative

Limitations:

- Does not solve complex problems

- Benefits can diminish without cultural reinforcement

Lean: Best for End-to-End Process Efficiency

Advantages:

- Focuses on customer value

- Eliminates waste

- Improves flow and responsiveness

- Scalable across departments and industries

Ideal Use Cases:

- Supply chain and logistics optimization

- Order fulfillment and customer service operations

- Administrative processes (e.g., procurement, HR)

- Production environments with flow variability

Limitations:

- May lack statistical depth (compared to Six Sigma)

- Requires strong cultural adoption

- Can be difficult to sustain without leadership support

Kaizen: Best for Cultural Transformation and Daily Improvement

Advantages:

- Empowers employees

- Low-cost, high-frequency improvements

- Strengthens collaboration and accountability

Ideal Use Cases:

- Operations seeking employee engagement

- Service centers and manufacturing cells

- Quality circles and shop floor meetings

Limitations:

- Small-scale improvements may lack strategic alignment

- Requires consistent discipline and management buy-in

TPM: Best for Equipment Reliability and Productivity

Advantages:

- Reduces unplanned downtime

- Extends equipment life

- Improves product quality

- Builds operator ownership

Ideal Use Cases:

- High-volume manufacturing plants

- Facilities with high capital investment in equipment

- Environments requiring zero-defect production (e.g., automotive, electronics)

Limitations:

- Requires significant training and cross-functional coordination

- Benefits take time to materialize

TOC: Best for Managing Bottlenecks and Maximizing Throughput

Advantages:

- System-wide perspective

- Rapid prioritization

- High impact on throughput and profit

Ideal Use Cases:

- Project management (Critical Chain Project Management – CCPM)

- Capacity-constrained operations

- Make-to-order production environments

Limitations:

- May overlook quality or waste

- Not well-suited for highly flexible operations with shifting constraints

Integrating Methodologies: Synergies and Combined Approaches

Rather than selecting one methodology in isolation, many world-class organizations deploy integrated programs that blend elements of Six Sigma, Lean, 5S, TPM, and TOC.

Example Integrations:

- Lean Six Sigma: Combines Lean’s focus on speed and flow with Six Sigma’s focus on quality and precision.

- 5S + TPM: Clean, organized environments support autonomous maintenance and prevent downtime.

- Lean + TOC: TOC identifies bottlenecks while Lean streamlines the surrounding processes.

- Kaizen + Any Framework: Kaizen culture supports the continuous execution of all improvement initiatives.

Maturity Model Considerations:

Organizations often implement these frameworks in a maturity progression:

- 5S – Start with basic workplace discipline.

- Kaizen – Build a culture of small daily improvements.

- Lean – Eliminate systemic waste and improve flow.

- TPM – Maximize asset effectiveness.

- Six Sigma – Address precision and eliminate defects.

- TOC – Systematically optimize constraints for maximum throughput.

Strategic Considerations When Selecting a Methodology

Nature of the Problem

- Complex, data-driven quality issues → Six Sigma

- Messy, unsafe, or inefficient environments → 5S

- Excessive delays, waiting, or overproduction → Lean

- Repetitive equipment failures → TPM

- Resource bottlenecks → TOC

Organizational Readiness

- Early in journey → Start with 5S and Kaizen

- Strong leadership and data → Embrace Six Sigma

- High visibility to frontline workforce → Prioritize Kaizen

- Capital-intensive plant → TPM is critical

- Mature CI culture → Combine Lean Six Sigma with TOC overlay

Industry Sector

- Manufacturing → Lean, TPM, Six Sigma

- Healthcare → Lean, Six Sigma

- Logistics → 5S, Lean, TOC

- Financial Services → Six Sigma, TOC

- Retail & E-commerce → Lean, 5S, Kaizen

Conclusion

Continuous improvement is not a one-size-fits-all endeavor. Each methodology, whether it be Six Sigma’s analytical rigor, Lean’s waste-focused philosophy, 5S’s organizational discipline, TPM’s maintenance excellence, TOC’s systems thinking, or Kaizen’s cultural ethos, offers unique strengths. The key to sustainable success lies in selecting the right tool for the right problem, aligning with organizational maturity, and fostering a culture of continuous, participatory improvement.

Rather than choosing between methodologies, modern operations leaders should adopt a strategic mix, leveraging their synergies to drive breakthrough improvements across people, process, systems, and infrastructure. In doing so, they can build a resilient, responsive, and high-performing supply chain and operational ecosystem.