Pallet storage racks are the unsung heroes of any warehouse operation. As the foundation of material handling and inventory storage, the right racking system can improve efficiency, protect inventory, and optimize floor space. However, choosing the right system is not as straightforward as it once was. In today’s rapidly evolving supply chain landscape, where space constraints, labor shortages, and automation are influencing design decisions, understanding the types of racking and their applications is more critical than ever.

Structural Steel vs. Roll-Formed Racking: Know the Difference

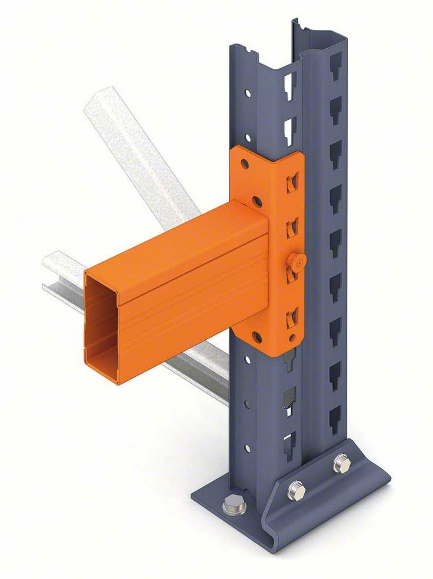

The two primary types of pallet rack construction are structural steel (hot-rolled) and roll-formed (or cold-rolled) steel. Each has distinct characteristics that may have bearing on your application and decision-making process.

Roll-Formed Racking

This is the most common type of racking in use. Manufactured by feeding light-gauge coiled sheet steel through roll-forming machines, the resulting components derive their strength primarily from their shape rather than their thickness. Roll-formed systems are lighter, more cost-effective, and typically easier to install and reconfigure (since beams are typically attached to uprights with some variation of a keyhole and rivet connection), making them more flexible for operations with changing pallet sizes or frequent re-slotting. It is important to note that changing beam elevations may alter the load-carrying capacity of a system that has been engineered based on a specific number and location of beams. Consult your rack supplier or structural engineer.

Structural Steel Racking

Made from hot-rolled steel components such as C-channels, structural racking is significantly heavier and more robust. Its rugged design provides superior resistance to damage, particularly from forklift impacts. Even if deformed, structural racks may retain up to 80% of their rated capacity until repairs can be made. This durability makes structural racking well-suited for high-traffic, high-impact environments, such as cold storage, beverage distribution, and industrial manufacturing. Connections between beams and uprights are typically nuts and bolts.

Hybrid Systems

For facilities seeking the best of both worlds, hybrid racking systems offer a compelling middle ground. These systems typically feature structural steel uprights for impact resistance combined with roll-formed beams to reduce weight and cost. This configuration strikes a balance between durability, flexibility, and cost efficiency.

Balancing Selectivity and Storage Density

Choosing the right racking type goes beyond material; it’s also about how you want to store and access your products. Key system types include:

-

Selective Racking – Offers the highest selectivity and is ideal for high-SKU, low-volume/inventory depth environments.

-

Double-Deep – Increases storage density while reducing selectivity.

-

Push-Back – Allows for LIFO (last-in, first-out) inventory management with higher density.

-

Drive-In / Drive-Through – Maximizes space utilization for large volumes of similar products.

-

Pallet Flow (Gravity Flow) – Supports FIFO (first-in, first-out) inventory rotation and high throughput.

Your inventory profile, including SKU velocity, turnover rate, and batch size, should guide your racking strategy. The right configuration will strike a balance between selectivity (ease of access) and density (efficient space utilization).

Lift Truck Compatibility and Aisle Design

No racking system exists in a vacuum. Aisle widths, ceiling height, and lift truck types must all be engineered in harmony. From traditional counterbalance forklifts to reach trucks, swing-mast (turret) trucks, and automated guided vehicles (AGVs), each equipment type has unique turning radii and operational requirements.

For example:

-

Narrow-aisle (NA) and Very Narrow-Aisle (VNA) racking may necessitate specialized lift trucks capable of working in reduced aisle widths and reaching top shelf elevations. Wire-guidance may also be necessary in the case of VNA.

-

High-density systems may benefit from automation (driverless) or semi-automation.

-

Forklift impact risk should influence the choice of upright material as well as the design of impact protection at floor level and end of aisle.

Compliance and Safety Considerations

Beyond performance, all racking systems must comply with Federal, State, and Local building and life-safety codes. In the U.S., racking should meet standards set by the Rack Manufacturers Institute (RMI) and the American Institute of Steel Construction (AISC). Proper seismic design, fire safety, and load certification are non-negotiable aspects of any warehouse storage system. Rack manufacturers/suppliers should be charged with meeting/exceeding these mandates as well as Federal, State, and Local building and life safety codes. Vendors should prepare signed and sealed engineering drawings and include seismic calculations.

No One-Size-Fits-All Solution

There is no universal answer to pallet rack design. Every warehouse has unique demands based on its products, workflows, equipment, and expansion plans. That’s why a thoughtful, data-driven approach—ideally involving warehouse design experts, engineers, and operations managers—is essential to selecting a system that will grow with your business and deliver long-term ROI.

Conclusion

Whether you’re building a new facility or retrofitting an existing one, investing in the right pallet racking system is foundational to warehouse efficiency and safety. By understanding the trade-offs between structural and roll-formed racking, aligning your system to inventory flow, and ensuring code compliance, you can make an informed decision that will serve your operations well for years to come. OPSdesign Consulting is an independent supply chain and warehouse design consulting firm. We design optimal rack system layouts and develop functional specifications to facilitate a competitive bid process among vendors.